With innovations in molecular design and device engineering, the photoelectric conversion efficiency (PCE) of organic solar cells (OSCs) has exceeded 18%. A bulk heterojunction (BHJ) structure is adopted in the photoactive layer of high-performance OSCs, in which the donor (D) and acceptor (A) materials can form an interpenetrating network with a large D/A interfacial area through mixed casting (BC). , which contributes to exciton dissociation. However, how to delicately balance the self-aggregation and miscibility of the two components during the one-step deposition process is a challenge, which involves complex kinetic processes. Therefore, the photovoltaic performance of BC-treated devices is highly dependent on the conditions of the main solvent, the mixing ratio of D/A materials, processing additives, and post-treatment. Therefore, it is difficult to control the morphology of the film to a certain extent, especially the D/A distribution in the vertical direction of the BC film, which is closely related to the transport and collection of charges.

To effectively tune the vertical phase distribution, the sequential deposition (SD) method of D and A materials is considered as an alternative to the BC process. Since the deposition of D and A can proceed independently, favorable vertical phase distribution and improved film morphology are formed, thus providing sufficient D/A interfacial area and direct transport paths for charge carriers. Therefore, the optimal vertical morphology of SD films can reduce energy loss, provide excellent charge transport and extraction, and in turn obtain ideal open circuit voltage (VOC), short circuit current density (JSC) and fill factor (FF), and ultimately improve device performance.

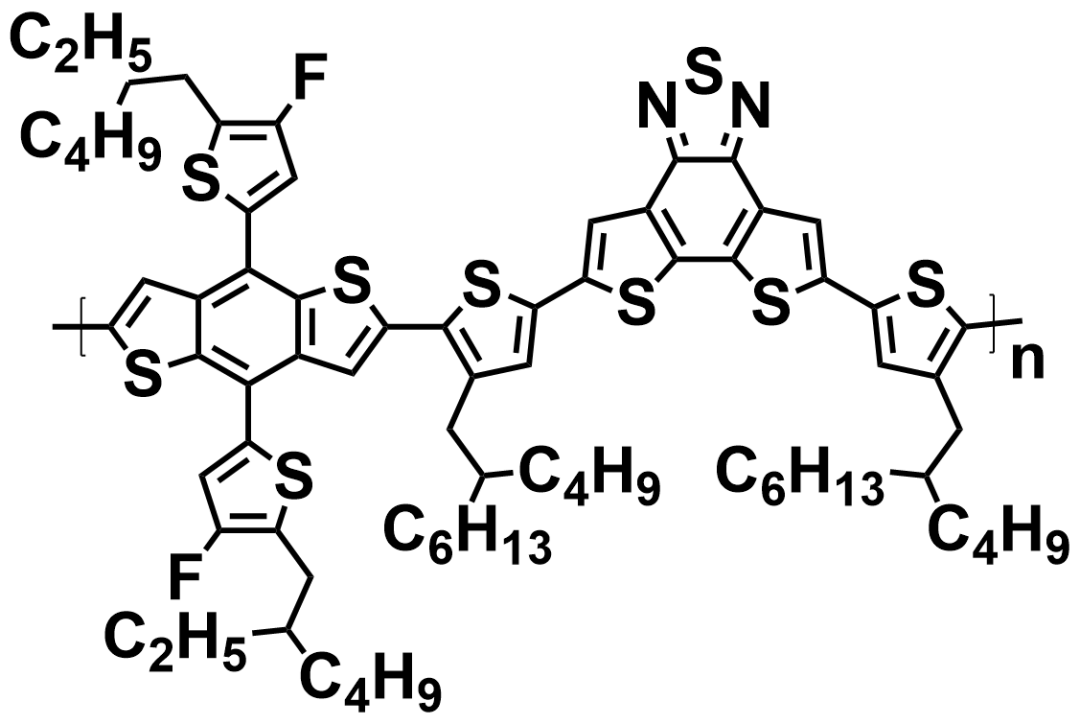

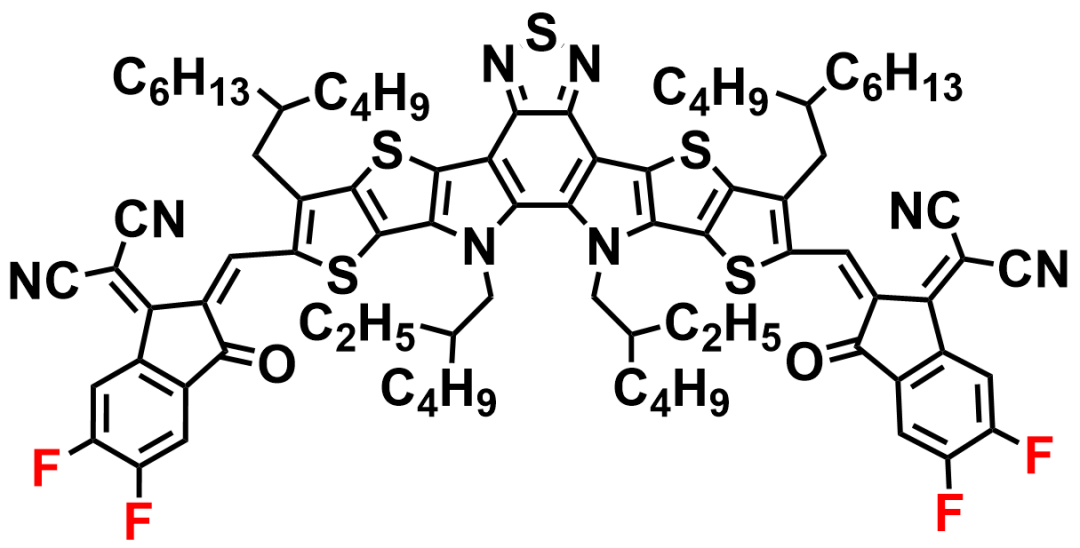

Figure 1. Material structure and basic properties

2. Literature introduction

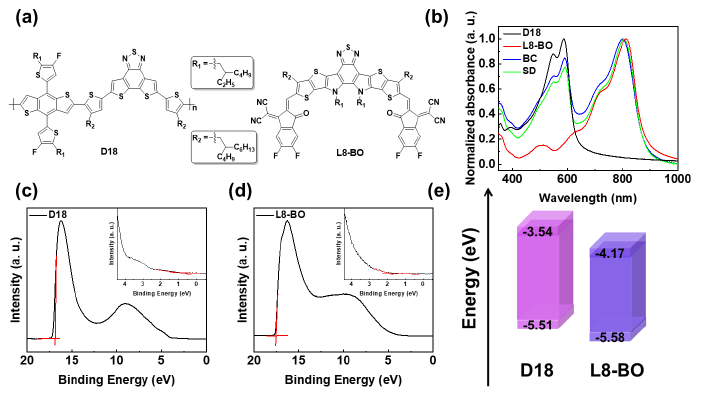

In view of this, recently, the research team of Professor Huang Hui and Associate Professor Zhang Xin of the University of Chinese Academy of Sciences constructed a high-performance binary photovoltaic device based on D18 and L8-BO through two-step SD processing. After adjusting the spin coating speed for each film deposition, the SD films exhibited preferential vertical phase separation and well-controlled D/A film morphology. Therefore, the PCE of the best device is 19.05% (certified efficiency is 18.9%), which is the highest efficiency for binary single-junction OSCs so far. Mechanistic studies have shown that this treatment method effectively tunes the vertical composition distribution of the active layer for higher crystallinity, efficient exciton splitting, low energy loss, and balanced charge transport, which is beneficial to the VOC, JSC of the device. and FF. Impressively, this vertical component distribution regulation strategy exhibits excellent versatility in enhancing the photovoltaic performance of OSCs.

图2.器件结构与薄膜成分分布

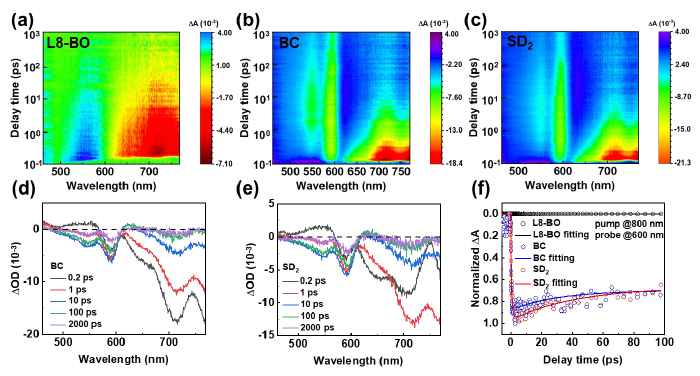

Figure 3. Transient absorption spectrum and hole transport process

3. Literature summary

In conclusion, this work proposes a simple and effective strategy to enhance the photovoltaic performance of OSCs by regulating the vertical composition distribution of the active layer. Relevant research results were recently published in the top international journal "Advanced Materials", entitled "Binary Organic Solar Cells Breaking 19% via Manipulating Vertical Component Distribution".

Keywords in this paper: organic solar cells, binary components, sequential deposition, vertical components.

4. Material recommendation

|

|

D18 | L8-BO |