Organic solar cells (OSCs) have attracted extensive attention due to their low cost, light weight, and flexible fabrication. With the development of materials and device engineering, the energy conversion efficiency of single-junction organic solar cells has exceeded 18%. In conventional bulk heterojunction (BHJ) structured organic solar cells, the random phase separation of the acceptor severely affects the morphology of the thin film, thereby affecting the efficiency and stability of the solar cell. In recent years, spin-coating the receptor layer by layer to prepare a device with a layered structure (SD device) is beneficial to control the morphology of each layer, achieve balanced charge transport, and direct transport channels, thereby improving the stability of the device. performance and efficiency. Therefore, a series of methods including vacuum deposition, thin film transfer, and orthogonal solvents have been used to fabricate layered OSCs, and significant research progress has been achieved. However, most of these methods are not universal and difficult to apply to all donor-acceptor systems, so there are limitations in commercial application.

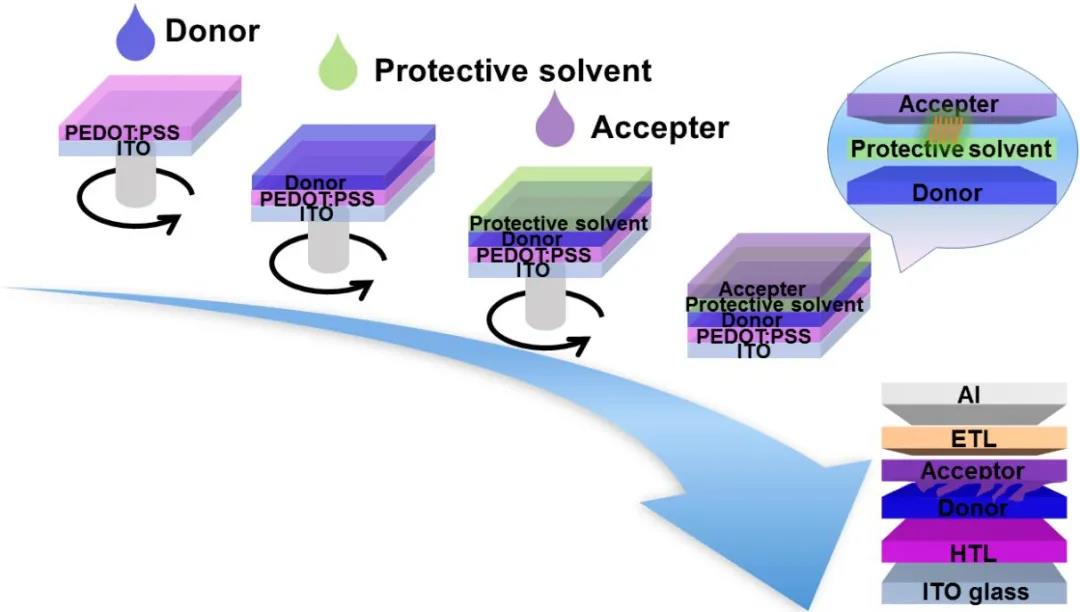

Recently, the team of Professor Hui Huang from the University of Chinese Academy of Sciences and his collaborators have developed a general method for the preparation of organic solar cells with a layered stack structure, and named it an environmentally friendly solvent protection method (ESP). The method utilizes an environmentally friendly solvent as a protective layer between the donor and acceptor, thereby fabricating high-performance vertical phase-separated structured layered devices. By studying the difference in the protective effect of different protective solvents on the donor film, the optimal protective solvent was screened out, and its mechanism was further studied.

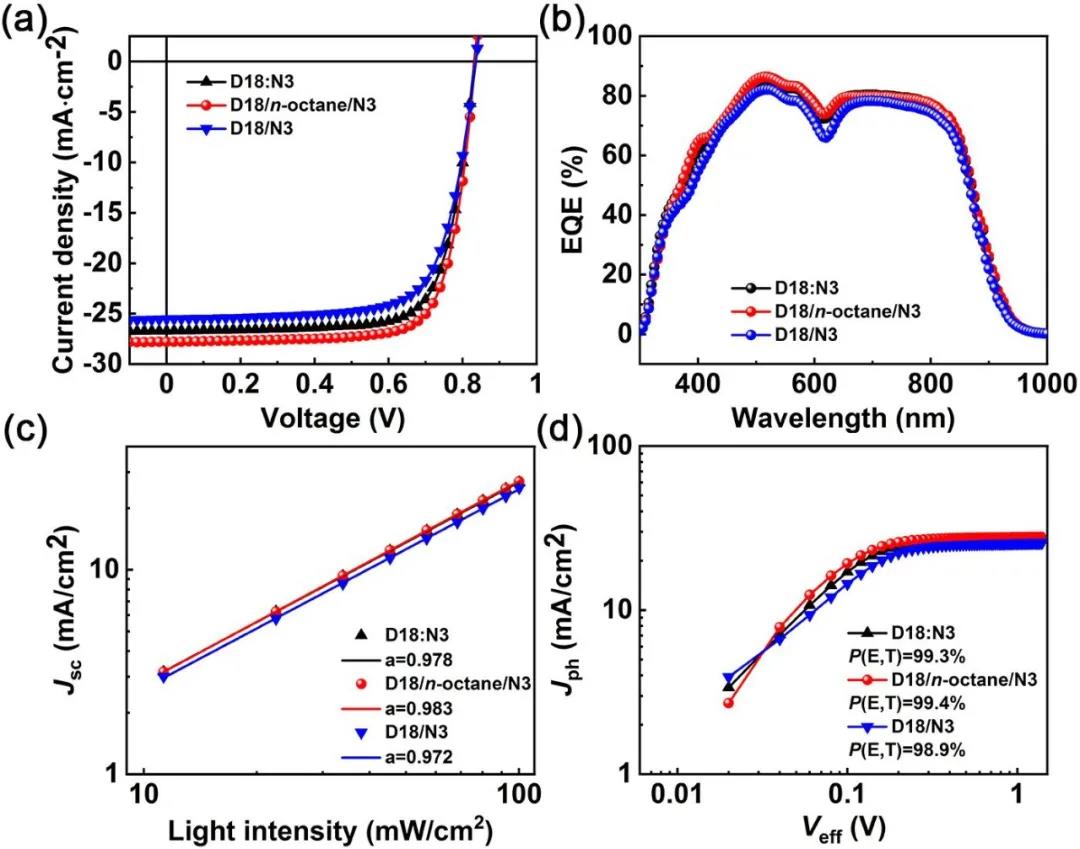

Based on D18 and N3 systems, BC devices and SD devices with/without protective solvent were prepared, respectively. The n-octane screened out of 8 protective solvents has the best protective performance. The SD device (D18/n-octane/N3) with n-octane as the protective solvent has the best photovoltaic performance, and its corresponding EQE spectrum can reach more than 80% and reach 86% at 520nm; the device has a weaker The recombination and high exciton dissociation efficiency of the device; the energy conversion efficiency (PCE) of the device reaches 17.52%, the corresponding open circuit voltage (VOC) is 0.834 V, and the short circuit current (JSC) is of 27.79 mA/cm2, filling factor (FF) is of 75.61%, which is the highest efficiency of OSCs prepared by layer-by-layer spin coating. Further studies show that the ESP method is universal to multiple donor-acceptor material systems of fullerenes and non-fullerenes, which is beneficial for future commercial applications.

In the ESP method, the protective solvent should satisfy both conditions:

1. The protective solvent has good spreadability on the surface of the donor film;

Second, in the spin coating process, the protective solvent cannot be completely volatilized.

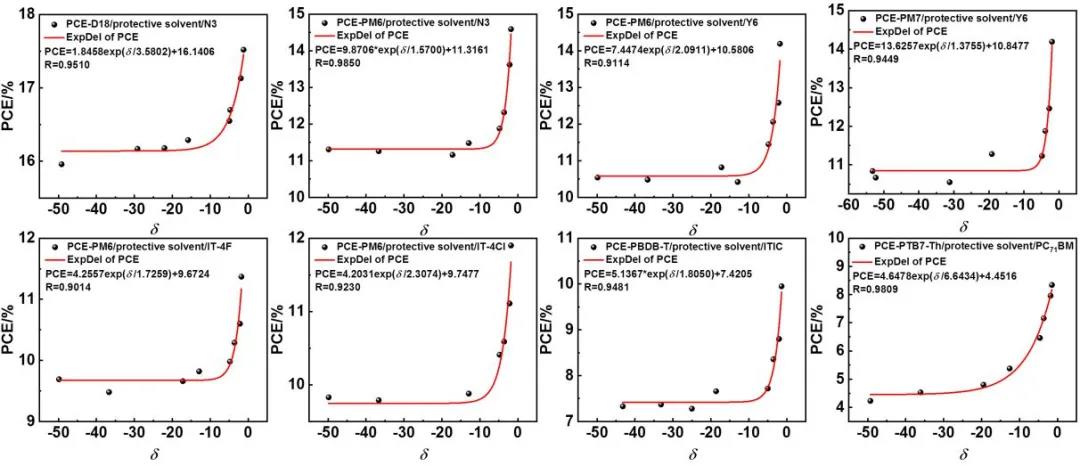

Therefore, the spreading coefficient (S) of the protective solvent on the surface of the donor film and the volatility (P) of the solvent are of interest. Thus, a new parameter, the protection factor (δ), is defined.

This parameter is used to measure the protective properties of the solvent to the donor material. Moreover, this work established the relationship between protective factor δ and PCE quantification, and extended it to multiple donor-acceptor systems. The proposed protection factor provides an idea for understanding the mechanism of ESP method and the choice of protection solvent.

The above related results were recently published online in Energy & Environmental Science, a well-known journal of energy and environment. The first author of the paper is Wei Yanan, a 2019 doctoral student at the School of Materials Science and Optoelectronic Technology, University of Chinese Academy of Sciences. The corresponding authors are Professor Huang Hui of University of Chinese Academy of Sciences, Professor Gao Feng of Linköping University and Professor Ding Liming of National Nanoscience Center. The above research work has been supported by the key research and development plan of the Ministry of Science and Technology, the National Natural Science Foundation of China and the relevant funds of the Academy of Sciences.