Thanks to the joint efforts of molecular design and device engineering, the power conversion efficiency (PCE) of organic solar cells (OSCs) has increased dramatically. However, with the current high efficiency, there are still challenges in achieving high-throughput commercial production of OSCs. The active layer thickness of current high-efficiency devices is in the range of 100-120 nm, which will lead to underutilization of the incident photon flux. In addition, there are difficulties in obtaining defect-free, uniform films in commercial production, and the thickness of the active layer can often reach hundreds of nanometers. Therefore, the development of efficient thick-film organic solar cells is crucial to realize OSCs from laboratory to commercial production. In this article, the oligomeric acceptor material DY-TF containing S···F conformational lock was selected as the third component to prepare a high-performance thick film device. The introduction of DY-TF promotes the generation and transmission of charges in the ternary system and inhibits charge recombination, which is beneficial to the improvement of photovoltaic performance. A thick film (300 nm) device based on PM6:L8-BO:DY-TF achieved a PCE of 18.23% (certified efficiency of 17.8%), which is the highest efficiency reported so far for a 300 nm thick film OSC. This work resulted in OSC devices with higher film thickness tolerance, which indicates a brighter future for the commercial production of OSCs.

Recently, our team published an opinion article titled "Over 18% Efficiency Ternary Organic Solar Cells with 300 nm Thick Active Layer Enabled by An Oligomeric Acceptor" in the internationally renowned journal Advanced Materials. This opinion article uses oligomeric acceptor materials as the third component to prepare high-performance thick-film organic solar cells, achieving an energy conversion efficiency of 18.23% (300 nm), and improving charge generation, transport, and recombination inside the device. The process was systematically studied.

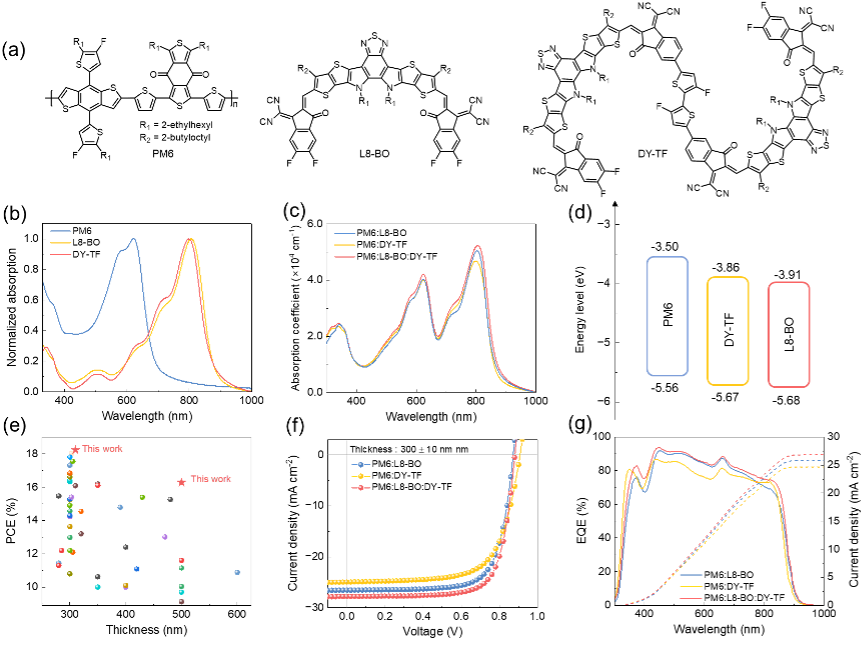

Figure 1. Molecular structure, absorption, energy level and device performance used in high-performance thick film organic solar cells.

Point 1: Device performanceThe oligomeric receptor material DY-TF has a good planar structure and a high glass transition temperature (Tg=231°C). The thin-film (110 nm) organic solar cell (PM6:L8-BO:DY-TF) prepared with it as the third component achieved an energy conversion efficiency of 19.13%, with an open-circuit voltage of 0.905 V and a short-circuit current of 26.93 mA• cm-2, the fill factor is 78.50%; the PCE of the corresponding thick film (300 nm) OSC is 18.23% (certified efficiency is 17.8%), its open circuit voltage is 0.884 V, short circuit current is 27.80 mA·cm-2, filled factor of 74.18%, which is the highest efficiency reported so far for thick-film OSCs; the corresponding large-area (1cm2) and doctor blade (DB)-coated thick-film (300 nm) OSCs achieved PCEs of 15.49% and 17.38%, respectively. , which are the highest efficiency values for thick-film OSCs treated with large area and DB, respectively. The introduction of DY-TF is beneficial to promote the charge generation and transport inside the ternary film, inhibit charge recombination, and thereby obtain excellent photovoltaic performance.

Point two: Morphology research According to atomic force microscopy analysis, with the addition of DY-TF, the ternary blend film exhibits an obvious nanofiber network structure, which is conducive to effective exciton dissociation and charge transport. L8-BO and DY-TF have similar skeleton structures, giving them good mutual solubility. According to wide-angle x-ray diffraction (GIWAXS) analysis, the coherence constant (CCL) of the lamellar stacking peak of the ternary hybrid film increased from 86.071Å to 88.123Å, and the CCL value of the π-π stacking peak increased from 21.518Å to 23.015Å. The excellent molecular crystallinity in the ternary blend facilitates charge transport inside thick-film OSCs.

Point 3: Theoretical calculationIn addition, to further study the impact of the addition of DY-TF on the active layer, we performed molecular dynamics (MD) simulations. The results show that after adding DY-TF in the PM6:L8-BO film, the center of mass (COM) distance between PM6 and L8-BO decreases from about 2.10 nm in the PM6:L8-BO film to PM6: 1.16nm in the L8-BO:DY-TF film, indicating that the molecular stacking of the PM6:L8-BO:DY-TF film is closer than that of the PM6:L8-BO film. According to the mass density results at the relative positions of the model center, after adding DY-TF, the fluctuation of the mass density of the ternary film is relatively small, indicating that the ternary film has a more uniform density than the main binary film (PM6:L8-BO) distributed. The close stacking and uniform density distribution of ternary films are beneficial to the charge transport behavior.

Point 4: Looking forwardCurrently, the performance of organic solar cells continues to improve, and thick-film devices have also achieved considerable photovoltaic performance. However, there are still problems with the long-term stability of thick-film organic solar cells. Since the material itself and the film morphology are sensitive to light, heat, and air, the commercial application of organic solar cells is still challenging. Further development of new material systems or new device structures are feasible strategies to obtain high-stability thick-film organic solar cells.

“Over 18% Efficiency Ternary Organic Solar Cells with 300 nm Thick Active Layer Enabled by An Oligomeric Acceptor”

Link: https://onlinelibrary.wiley.com/doi/10.1002/adma.202304225