【Background】

Organic solar cells (OSCs) have attracted widespread attention at home and abroad due to their light weight, inherent flexibility, and solution processability. Their power conversion efficiency (PCE) has exceeded 20%. However, high-performance OSC active layers usually require complex morphology optimization processes, such as the introduction of additives, thermal annealing, solvent annealing, etc. Additive residues have a negative impact on device stability. Thermal/solvent annealing is not compatible with roll-to-roll processing techniques. The difference in crystallinity between the polymer donor and the small molecule acceptor may cause the main chain conformation to be disordered, making it difficult to obtain the ideal active layer morphology without using additives and post-processing. Therefore, the development of high-performance organic solar cells (as-cast devices) with simple processes and no post-processing is not only the focus and difficulty of research in the field, but also an inevitable requirement for the commercial application of organic solar cells. This point of view improves exciton dissociation, charge transport, and reduces charge recombination in as-cast devices by constructing a dual-fiber network morphology and improving the dielectric constant strategy to obtain high-performance as-cast organic solar cells.

【Article introduction】

Recently, the research team published a perspective article titled "High Performance as-cast Organic Solar Cells Enabled by a Refined Double-fibril Network Morphology and Improved Dielectric Constant of Active Layer" in the internationally renowned journal Advanced Materials. This opinion article uses a high dielectric constant polymer acceptor material as the third component to construct a double fiber network morphology to prepare high-performance as-cast organic solar cells.

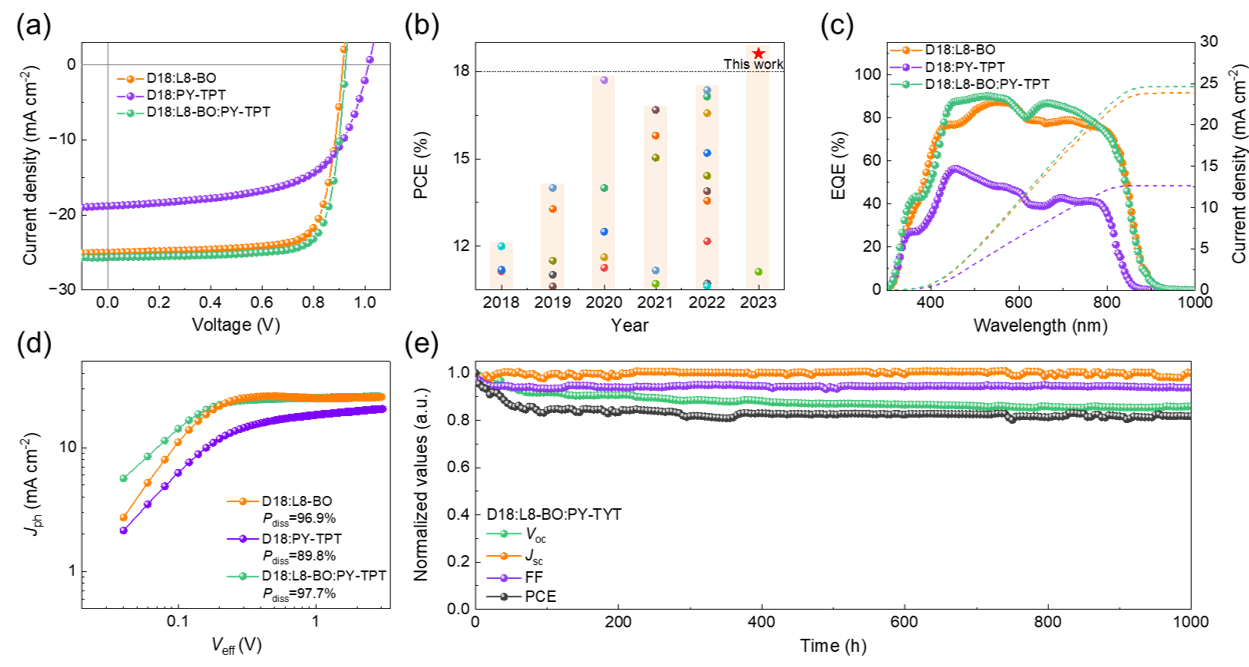

Figure 1. High-performance as-cast organic solar cells.

【Key points of this article】

Point 1: Device performance

The energy level position of the polymer electron acceptor PY-TPT is -5.65/3.80 eV. Compared with L8-BO, the increased LUMO energy level of PY-TPT will help reduce the energy loss of the D18:L8-BO:PY-TPT device, thereby improving the performance of the corresponding device. The as-cast organic solar cell (D18:L8-BO:PY-TPT) prepared with it as the third component achieved an energy conversion efficiency of 18.60% (certified efficiency is 18.2%), and its open circuit voltage is 0.926 V. Short circuit The current is 25.67 mA·cm-2 and the fill factor is 78.27%, which is the highest efficiency of as-cast organic solar cells reported so far; corresponding green solvent (o-xylene) processing, thick film (300 nm) and mold group (16.60 cm2) OSC obtained PCE of 17.45%, 17.54% and 13.84% respectively. The introduction of PY-TPT is beneficial to promote the charge generation and transport inside the hybrid film, inhibit charge recombination, and thereby obtain excellent photovoltaic performance.

Point 2: Energy loss

In the theory derived under the framework of Marcus theory, the energy loss is analyzed in detail using electroluminescence (EL) and highly sensitive external quantum efficiency characteristics to gain in-depth understanding of the Voc differences of as-cast devices. The total energy loss (Eloss = ECT – qVoc) consists of two main contributions: one is the radiative energy loss (ΔEr) and the other is the non-radiative energy loss (ΔEnr). By fitting the highly sensitive external quantum efficiency tail state and the electroluminescence (EL) spectrum, the charge transfer (CT) state energy of the D18:L8-BO, D18:PY-TPT and D18:L8:BO:PY-TPT systems (ECT) are 1.392, 1.449 and 1.391eV respectively. The ΔEr and ΔEnr of the D18:L8-BO:PY-PT device are 0.194 eV and 0.271 eV respectively, which are lower than the D18:L8-BO device (0.199 eV and 0.278 eV). Therefore, the total voltage loss in the D18:L8:BO:PY-TPT device (0.465 eV) is lower than that of the D18:L8-BO device (0.477 eV), which is consistent with the higher Voc of the three-element device.

Point 3: Morphology study, dielectric constant

The donor/acceptor phase separation in the active layer was further investigated through PiFM testing with near-field infrared imaging. After introducing PY-TPT into the D18:L8-BO film, the film exhibits a bicontinuous dual fiber network morphology. More importantly, the fibril diameters of 18.4 nm (donor) and 16.6 nm (acceptor) of the D18:L8-BO:PY-TPT film are larger than those of the D18:L8-BO film (17.0 nm donor and 13.0 nm acceptor). ) are larger and better matched, which is beneficial to efficient exciton dissociation and charge transport.

Increasing the dielectric constant (εr) will help reduce the binding energy of CT excitons. Compared with L8-BO film (εr = 3.91), PY-TPT has a larger dielectric constant (εr = 4.71). With the introduction of PY-TPT, the dielectric constant of the D18:L8:PY-TPT film (εr = 4.82) has improved compared to the D18:L8-BO film (εr = 4.17). Therefore, the reduced binding energy is beneficial to improving charge extraction and reducing charge recombination, which is beneficial to improving the photovoltaic performance of as-cast devices.

Point 4: Looking forward

At present, the performance of organic solar cells continues to improve, and as-cast devices have also achieved considerable photovoltaic performance. However, the influence mechanism of the micromorphological evolution of as-cast films on device performance has not been clear yet. Therefore, it is very important to develop new in-situ dynamic characterization technology to achieve the mechanism analysis of "molecular structure-micromorphology-device performance" under the real working conditions of organic solar cells. Exploring the mechanism of molecular structure on the microscopic morphology of thin films and revealing the influence mechanism of nanofiber network morphology on device performance will further promote the development of new high-performance as-cast organic solar cells.

【Link】

High Performance as‐cast Organic Solar Cells Enabled by a Refined Double‐fibril Network Morphology and Improved Dielectric Constant of Active Layer

https://onlinelibrary.wiley.com/doi/10.1002/adma.202403294